Layin noman tumatir mai karfin tan 1000 a kowace rana

- Yanayi:

-

Sabo

- Wurin Asali:

-

Shanghai, China

- Sunan suna:

-

OEM

- Lambar Misali:

-

JUMP-FQJL050

- Rubuta:

-

Layin samar da tumatirin ketchup

- Awon karfin wuta

-

220V / 380V

- Powerarfi:

-

120 kw

- Nauyi:

-

100 TON

- Girma (L * W * H):

-

2100 * 1460 * 1590mm

- Takardar shaida:

-

ISO 9001, CE

- Garanti:

-

1 Shekara

- An bayar da Sabis ɗin bayan-tallace-tallace:

-

Injiniyoyin da ake da su ga injunan sabis a ƙasashen ƙetare

- Sunan samfur:

-

Layin samar da tumatir

- Kayan abu:

-

304 Bakin Karfe

- Suna:

-

layin sarrafa tumatir

- Aiki:

-

Wanke Pulping yana mai da hankali Ciwon haifuwa

- :Arfin:

-

3 ton / h sabo ne tumatir na iya samar da tumatir mai nauyin 500kg

- Anfani:

-

Masana'antar sarrafa tumatir ta masana'antu

- Aikace-aikace:

-

chilli sauce, mashin apricot jam

- Steam Dumama:

-

Ee kuma tare da tukunyar jirgi

- Item:

-

Layin samar da tumatir na atomatik mai sarrafa kansa

- Fasali:

-

sabis na tsayawa ɗaya

- 3 Saita / Sets a kowane Wata layin noman tumatir

- Bayanai na marufi

- 1.Stable katako kunshi kare inji daga yajin aiki da lalacewa. Fim din filastik yana kiyaye na'ura daga damp da lalata. 3. Kunshin-ba tare da bincike ba yana taimakawa sassaucin kwastan mai santsi. 4 Za'a gyara babban inji a cikin kwantena ba tare da kunshin ba.

- Port

- Shnaghai

- Lokacin jagora :

- 60 -90 kwanaki

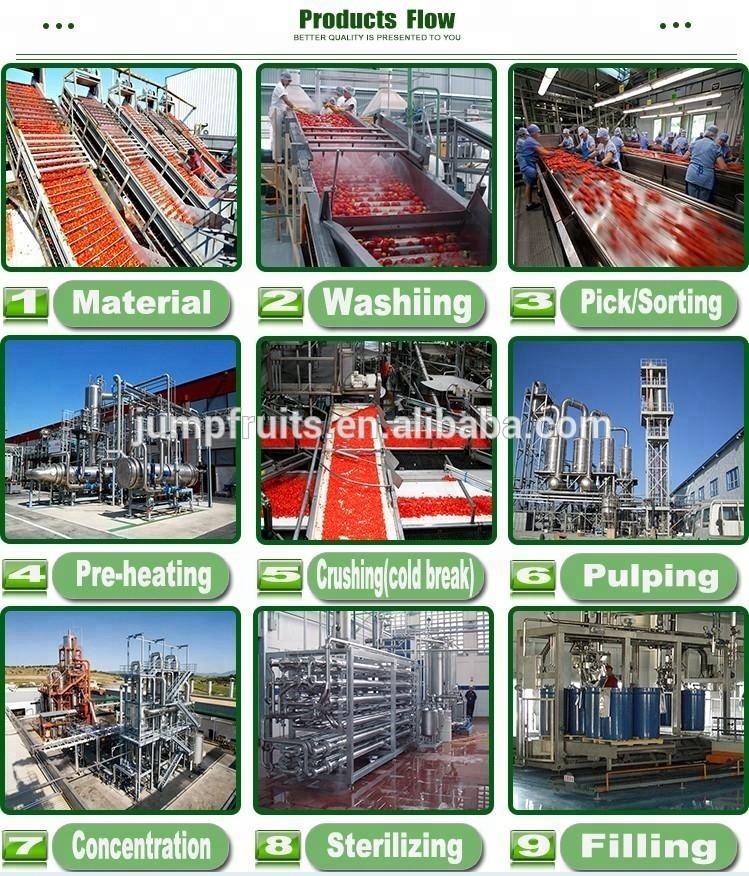

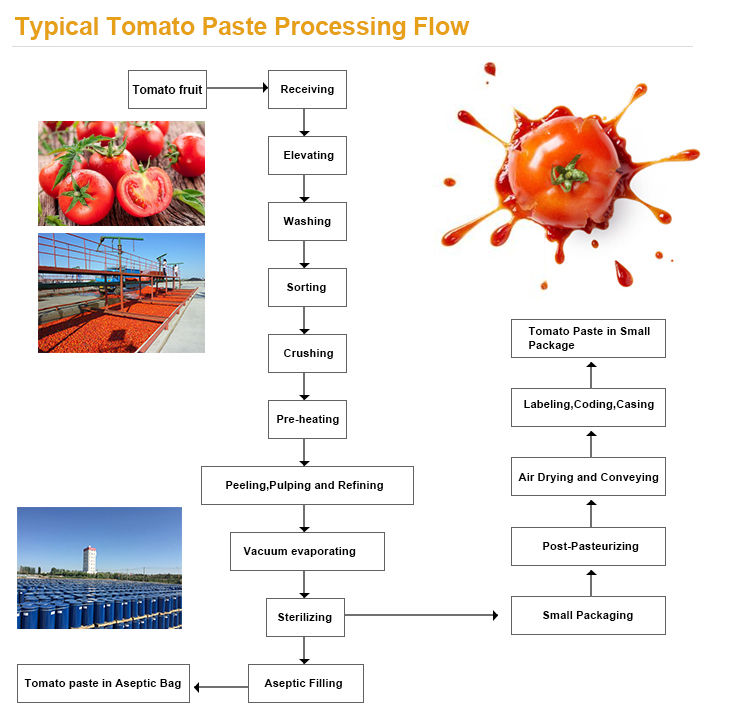

2.Dukkanin layin samarda tumatir:

A: tsarin gabatarwa na fruitsa fruitsan originala originalan asali, tsarin tsaftacewa, tsarin rarrabewa, tsarin murƙushewa, tsarin ƙararrawar pre-dumama, tsarin furewa, tsarin tattara ƙarancin wuri, tsarin haifuwa, tsarin cika jakar aseptic

B: famfo → hada ganga → homogenization → ciniki era injin haifuwa → injin wanka → cika inji → capping machine → rami fesa sterilizer yer bushewa ing coding → dambe

3. A karshe samfurin taro: Brix 28-30%, 30-32% sanyi ya karye kuma zafin ya karye, 36-38%

Injin wankin FreshTomato

Tumatir ana wanke shi da ruwa mai karfi a cikin injin wanki 'ya'yan itace Elevator mai ɗauke da tumatir yana isar da tumatir da aka tsabtace zuwa hanya ta gaba.

Sabbin Rarraba Rarraba Tumatir

Tsabtataccen 'ya'yan itacen sun shiga cikin injin daga hopper na ciyarwa, kuma suna juyawa gaba zuwa mashigar. Ma’aikata suna zaɓar tumatir marasa cancanta don tabbatar da ingancin samfurin ƙarshe.

Tumatirin Karyar Tumatir

An yi amfani dashi don isar da murƙushewar tomatos, ana shirya don dumama dumu da dasashi.

Preheater Tubular Tubular

Preheater na tubular yana kara yawan zafin jiki na almakashi ta hanyar dumama tururi, ta yadda zai tausasa ɓangaren litattafan almara da kashe enzyme.

Tumatir Single-tashar Pulping Machine

Ana amfani da inji mai daskarewa ta atomatik don rabuwa da ɓangaren litattafan almara da ragowar daga tumatir da aka niƙa da preheated. Kayan daga aikin karshe ya shiga cikin inji ta mashigar abinci, da kuma karkacewa zuwa mashiga ta hanyar silinda. Ta ƙarfin ƙarfin centrifugal, kayan abu ya huda. Thean litattafan almara ya ratsa sieve kuma aka aika shi zuwa aiki na gaba, yayin da fatar da ƙwaya aka sallamar ta hanyar ragowar, cimma manufar rabuwa ta atomatik. Za'a iya canza saurin bugun jini ta hanyar canza sieve da kuma daidaita kusurwar gubar mai shara.

Tumatir yana mai da hankali wajen fitar da injin ruwa

Ana amfani da wannan kayan aikin ne don ɗumbin ɗumbin tumatir ƙarƙashin ƙarancin zafin jiki. Ana shigar da Steam cikin jaket a ƙananan ɓangaren tukunyar jirgi, yana sanya kayan ƙarƙashin tafasa da ƙafe. Blender a cikin tukunyar jirgi yana taimakawa ƙarfafa kwararar kayan.

Tumatir manna tuber sterilizer

Tubular sterilizer tana kara yawan zafin jiki na hankali ta hanyar dumama tururi, cimma manufar haifuwa.

CIP mai tsabta tsarin

Semi-atomatik tsabtatawa tsarin

Ciki har da tankin acid, tankin tushe, tankin ruwan zafi, tsarin musayar zafi da tsarin sarrafawa. Tsaftace duk layin.

Tumatir manna ciko man inji da marufi

Musamman dacewa da manna tumatir, mangoro da sauran kayan viscous.

Kayan samfuran

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu